In the design and operation of modern industrial facilities, RAM analysis (Reliability, Availability, Maintainability Analysis) has become a vital tool for ensuring long-term stable operation, optimizing investment returns, and supporting decision-making. CIDIGITAL, leveraging its engineering expertise and data analytics capabilities, provides professional RAM analysis and safety analysis subcontracting services to clients in petrochemical, power, energy, offshore and other industries, helping improve system operation efficiency and reduce lifecycle costs.

文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

Service Overview

RAM analysis quantifies key indicators such as Reliability (R), **Availability (A)**, and **Maintainability (M)** under different operating conditions, simulates potential equipment failures and maintenance plans during actual operations, identifies system bottlenecks, optimizes design schemes, and formulates rational O&M strategies. CIDIGITAL’s RAM analysis services cover the entire lifecycle, including design, evaluation, and operation optimization, meeting clients’ needs for system reliability assessments at all stages.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

Core Service Content

🔹 System Modeling & Functional Decomposition: Build a functional block model of the entire system, defining logic structure, equipment configuration, and workflows.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

🔹 Critical Equipment Failure Data Collection: Gather and organize basic data like MTBF, MTTR, integrating industry standards and historical experience.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

🔹 Availability & Reliability Modeling & Simulation: Utilize specialized RAM tools to simulate and output system- and equipment-level reliability metrics.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

🔹 Bottleneck Identification & Failure Impact Analysis: Identify weak links affecting system availability and provide improvement suggestions.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

🔹 Maintenance Strategy & Redundancy Optimization: Optimize maintenance schedules and spare part strategies via scenario simulation.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

🔹 Customized RAM Evaluation Reports: Deliver decision-maker-oriented visual analysis reports to support strategic investment decisions.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

Commonly Used RAM Software

- RAM Commander

- Isograph Availability Workbench (AWB)

- Meridium APM Reliability

- DNV Maros

- ReliaSoft BlockSim

- GRIF Workshop / MAROS (for offshore use)

CIDIGITAL has modeling experience with all major RAM platforms and selects appropriate tools based on project needs.文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

Typical Deliverables

RAM Technical Proposal Document文章源自CIDIGITAL-https://www.cidrg.cn/en/services/engineering/620.html

System Logic Diagrams & Modeling Files

Simulation Results of Reliability & Availability

System Bottleneck Identification & Recommendations

O&M Optimization and Redundancy Suggestions

RAM Simulation Charts & Visual Materials

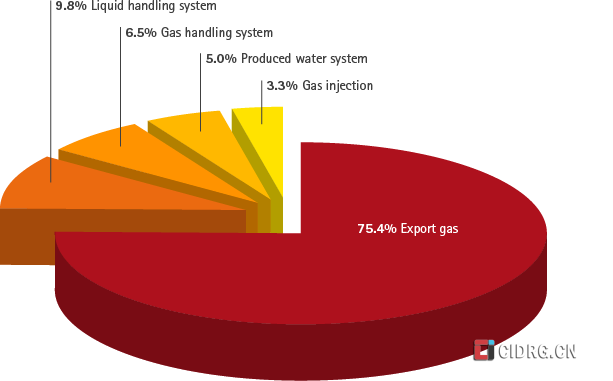

Case Study: RAM Analysis for a Natural Gas Processing Facility

In a large natural gas processing station project, the client required an annual system availability of over 98.5%. CIDIGITAL built a full-process RAM model, simulated system downtime under different maintenance strategies, and evaluated the redundancy configuration for key compressors and power systems. The optimized solution increased availability to 99.2% and reduced expected maintenance costs by nearly 15%.

Background

A large domestic natural gas processing station design project, with a total processing capacity of 1000×10⁴ Nm³/d, includes key units such as gas dehydration, desulfurization, condensate recovery, compression, and export. The client's project goals were:

Annual average plant availability ≥ 98.5%

Operating cycle goal: 3 years without shutdown

Achieve high reliability while controlling redundancy investment

Analysis Objectives

Perform RAM modeling analysis for the entire gas processing process

Identify critical equipment and process bottlenecks affecting availability

Optimize redundancy for major units (e.g., compressors, power systems)

Compare the impact of various maintenance strategies and resource allocations

Analysis Results & Optimization Recommendations

| Configuration Scheme | Annual Availability | Estimated Downtime | Additional Investment | Remarks |

|---|---|---|---|---|

| Single Machine | 96.8% | 288 hours | 0 million CNY | Not meeting target |

| Hot Standby | 98.7% | 113 hours | +9 million CNY | Meets requirement |

| Dual Redundant | 99.4% | 52 hours | +17 million CNY | High investment |

Recommended: Hot Standby Scheme:

Add one hot standby to compressors, condensate pumps, and power systems

Optimize dehydration system maintenance windows (night/low-load hours)

Introduce CBM (Condition-Based Monitoring) for key equipment

Client Feedback & Follow-Up

Client adopted the “Hot Standby” scheme as final design recommendation

RAM results included in feasibility report and used in project review

CIDIGITAL was invited to assist with O&M strategy formulation and RAM re-evaluation

Highlights Summary

Identified bottlenecks early (compressor single-point failure impact)

Proposed cost-effective solution (1.9% availability increase, ~18 months ROI)

Provided multi-scenario charts to support efficient decision-making

Service Advantages

✅ Extensive experience in process industries

✅ Multi-platform RAM modeling tool support

✅ Visualized output and decision-making assistance

✅ Cross-disciplinary collaboration (process, electrical, instrumentation, maintenance)

✅ RAM software training available

✅ Provision of RAM software training and technical support

Contact Us

If you are interested in RAM analysis technical services or wish to explore further cooperation, please contact CIDIGITAL through the following ways:

Official Website: www.cidrg.cn

Email: service@cidrg.com